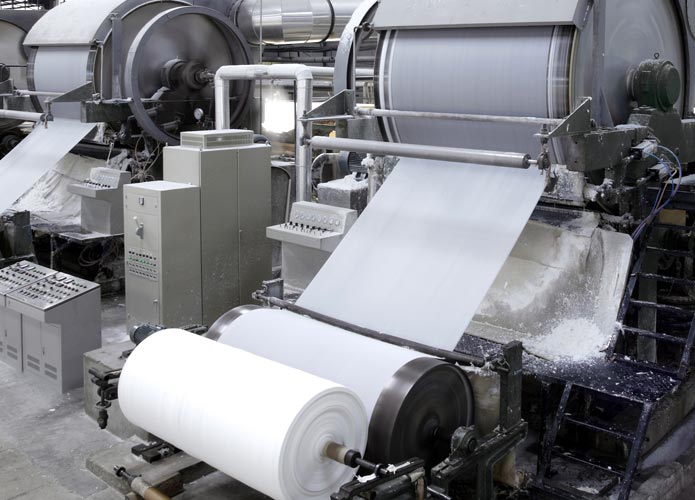

PULP AND PAPER

Large, spacious facilities with hot, steamy air and lots of fine paper particulate matter in the air characterizes pulp and paper manufacturing environments.

When a plant’s ability to meet ventilation and indoor air quality standards is hindered, the air movement equipment matters. And engineers and facility managers who care about their facilities’ air quality choose Hartzell Air Movement to provide solutions for their pulp and paper facilities.

Market Challenges

Delivering the industry’s toughest fans and blowers.

We leverage our creative design and savvy application expertise to provide products that solve your most pressing operational challenges.

SAFETY

Personnel safety—from less than optimal internal air quality—as well as routine maintenance are top priorities.

UPTIME

Reduced downtime of critical processes means improved performance and throughput, avoiding lost revenue.

OPERATIONAL BUDGET

Operating budgets are thin, with little resources to cover unplanned or unexpected maintenance, repair or replace costs.

- Safety

- Uptime

- Operational Budgets

Reduced downtime of critical processes means improved performance and throughput, avoiding lost revenue.

Operating budgets are thin, with little resources to cover unplanned or unexpected maintenance, repair or replace costs.

Market Solutions

State-of-the-art design and manufacturing

Savvy Hartzell Air Movement specialists are application-focused, air movement gurus. You get the best fan for pulp & paper industry applications—not just any fan that should get the job done. We apply the right fan design and components upfront. Designing, manufacturing and matching complementary components ensures a stable, reliable system to achieve and exceed air movement specifications.

The right products for pulp & paper applications

Hartzell designed these featured products to withstand tough pulp and paper industry applications.